Brass Gate Valves

Cast Iron Gate Valves

Cast Steel Gate Valves

Forged Steel Gate Valves

Stainless Steel Gate Valves

Rising Stem Gate Valves

Non-rising Stem Gate Valves

Double Disk Parallel Gas Gate Valves

Knife Gate Valves

Bellows Sealed Gate Valves

Cast Iron Globe Valves

Cast Steel Globe Valves

Forged Steel Globe Valves

Stainless Steel Globe Valves

Brass Globe Valves

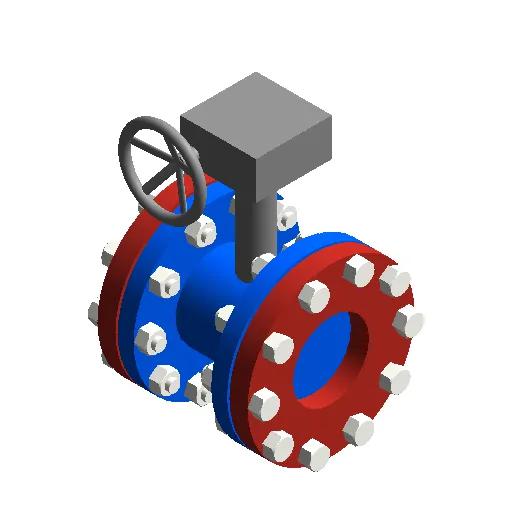

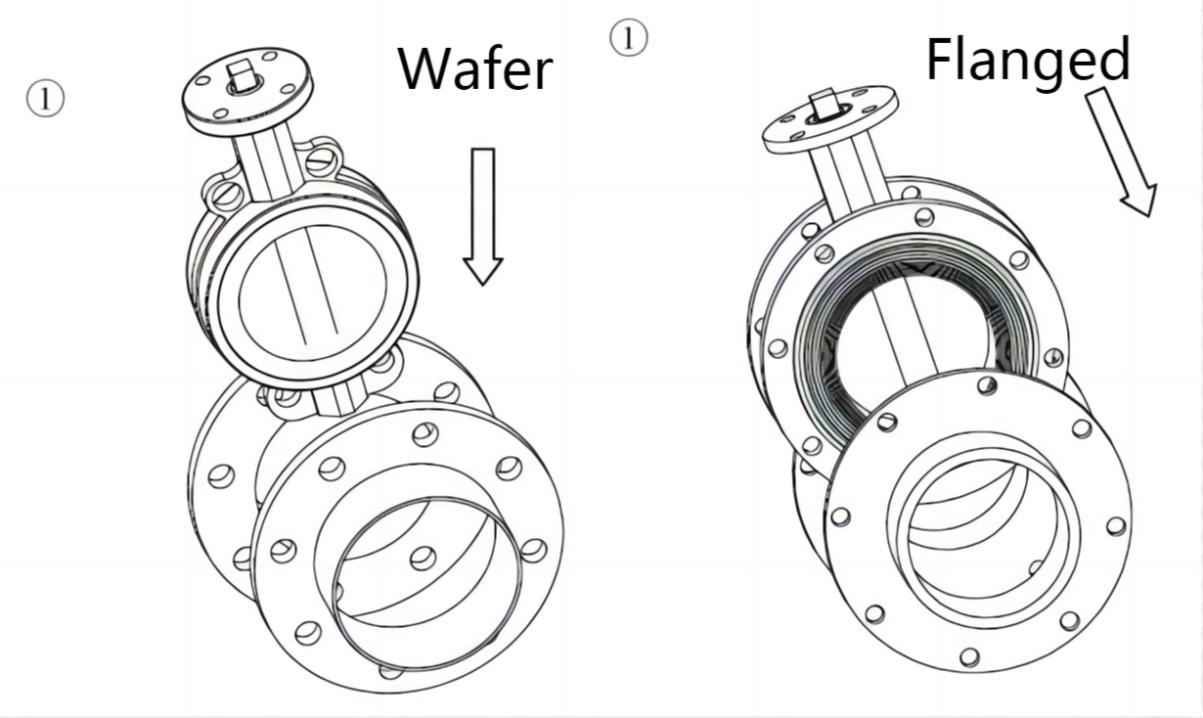

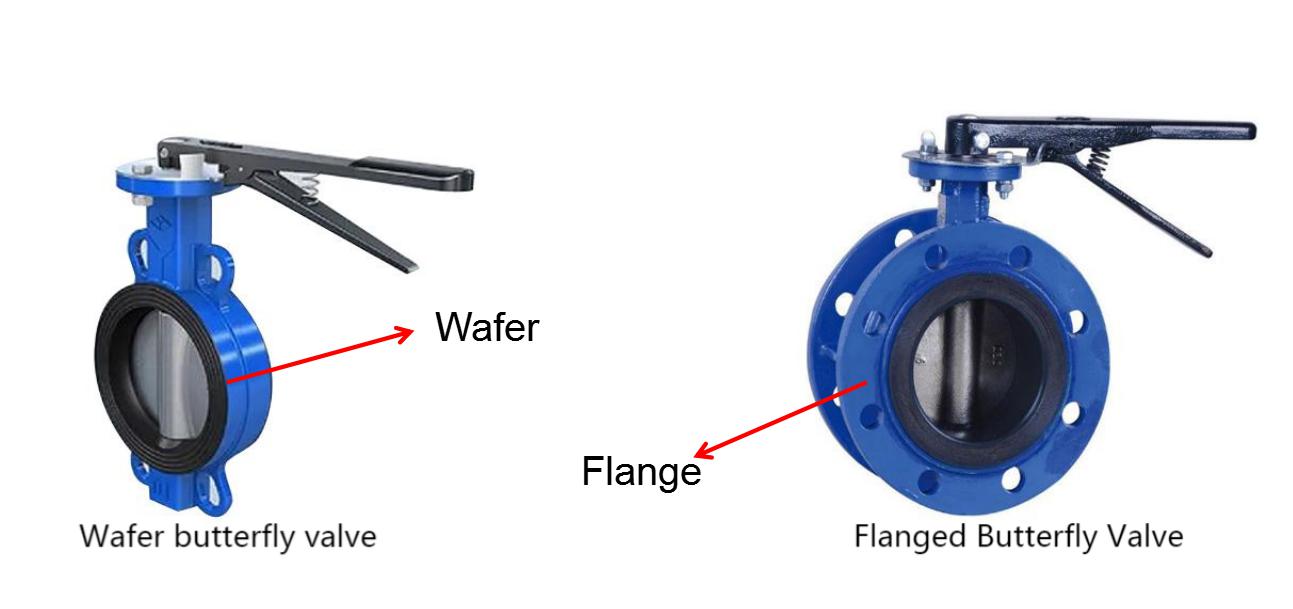

Wafer Type Butterfly Valves

Flange Type Butterfly Valves

Eccentric Butterfly Valves

Lug Type Butterfly Valves

Cast Steel Check Valves

Cast Iron Check Valves

Stainless Steel Check Valves

Brass Check Valves

Lift Check Valves

Swing Check Valves

Forged Steel Check Valves

Cast Iron Ball Valves

Cast Steel Ball Valves

Stainless Steel Ball Valves

Brass Ball Valves

Fully Welded Ball Valves

Electric Ball Valves

Ceramic Core Ball Valves

Multiport Ball Valves

Rotary Valves

Top Entry Ball Valves

Floating Ball Valves

High Pressure Ball Valves

High Temperature Ball Valves

V-port Ball Valves

Cast Iron Butterfly Balance Valve

Cast Iron Internal Thread Globe Balance Valve

Brass Balance Valve

Number-lock Balance Valve

Closed Spring Loaded Full Bore Type Safety Valve

Closed Spring Loaded Low Lift Type Safety Valve

High Temperature And High Pressure Safety Valve

Pilot Operated Safety Valve

Spring Full Bore Type Safety Valve With Radiator

Spring Full Bore Type With Lever Safety Valve

Spring Loaded Low Lift External Thread Type Safety Valve

Spring Loaded Low Lift Type Safety Valve

Spring Loaded Low Lift Type With Lever Safety Valve

Stainless Steel Spring Loaded Full Bore Type Safety Valve With Handle

Twin Spring Type Safety Valve

LNG Filling Nozzle

Cryogenic Gas Return Nozzle

Cryogenic Gas Refueling Receptacle

Cryogenic Gas Relief Valve

Cryogenic Gas Shut-off Valve

Cryogenic Gas Breakaway Coupling

Cryogenic Gas Pressure Regulator

Cryogenic Gas Check Valve

Flanges

日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย

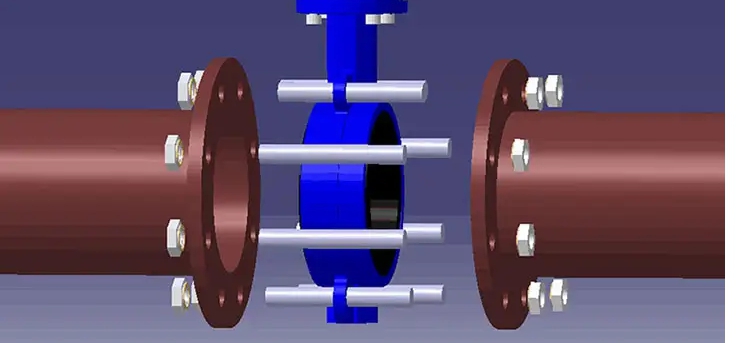

The wafer butterfly valve has no flange on its body, so its body structure length is relatively small, and it mainly depends on the extrusion of the flanges at both ends to achieve the sealing effect. Wafer butterfly valves usually use soft seals (non-metallic seals), which are mainly used in pipes with small diameters or low temperatures. Valves of this type of connection have high accuracy for construction and installation. If the pipe flanges on both sides are misaligned, there is a deviation, then the bolt will be subject to a large shear force when tightening, and the valve may leak; or work under high temperature working conditions, as the temperature rises, the bolt will expand with heat and contract with cold, such factors can also cause leakage in wafer style valves. From the perspective of installation, it is recommended to use less horizontal installation and more vertical installation. Wafer butterfly valves generally cannot be installed at the end of the pipeline and where the downstream needs to be disassembled, because when the downstream flange is removed, the wafer butterfly valve will fall off. In this case, it is necessary to make another pipe joint In order to disassemble, the flanged butterfly valve does not have the above problems, but the cost will be relatively high. Compared with valves of other connection methods, the production cost of clip-on butterfly valves is lower, and the later operation and maintenance are also more convenient. In the case of low production conditions, it is recommended to give priority to purchasing clip-on butterfly valves.

The wafer butterfly valve has no flange on its body, so its body structure length is relatively small, and it mainly depends on the extrusion of the flanges at both ends to achieve the sealing effect. Wafer butterfly valves usually use soft seals (non-metallic seals), which are mainly used in pipes with small diameters or low temperatures. Valves of this type of connection have high accuracy for construction and installation. If the pipe flanges on both sides are misaligned, there is a deviation, then the bolt will be subject to a large shear force when tightening, and the valve may leak; or work under high temperature working conditions, as the temperature rises, the bolt will expand with heat and contract with cold, such factors can also cause leakage in wafer style valves. From the perspective of installation, it is recommended to use less horizontal installation and more vertical installation. Wafer butterfly valves generally cannot be installed at the end of the pipeline and where the downstream needs to be disassembled, because when the downstream flange is removed, the wafer butterfly valve will fall off. In this case, it is necessary to make another pipe joint In order to disassemble, the flanged butterfly valve does not have the above problems, but the cost will be relatively high. Compared with valves of other connection methods, the production cost of clip-on butterfly valves is lower, and the later operation and maintenance are also more convenient. In the case of low production conditions, it is recommended to give priority to purchasing clip-on butterfly valves.