The graphene nanoplatelets(GNP) produced starting from natural flake graphite with physical stripping process to get graphene slurry,with the advantages of high purity, large specific surface area and high stability.The graphene nanoplatelets stripped by physical method have no oxidation process of strong oxidants, no lattice defects introduced, with excellent electrical conductivity.

For graphene nanoplatelets dispersion liquid, the most commonly used dispersant is water, while ethanol, ethyl, NMP, DMF, etc. can also be used as a dispersant. Graphene nanoplatelets dispersion is not stable, often need to add an appropriate amount of dispersing additives.

Item | Parameter |

Layers | 2~8 |

Particle size( D50=μm) | 7~12μm |

Dispersing agent | Deionized water |

Solid content (%) | <1 |

Appearance | Black liquid |

Preparation method | By physical method |

Raw material | Natural flake graphite |

Concentration of dispersant (mg/mL) | 0.5/1.0/2.0/5.0/10 |

Product Specification | 50ml/bottle,100ml/bottle,250ml/bottle,500ml/bottle,1000ml/bottle |

High product quality: no introduction of lattice defects;

Less impurity content: all-round control of metal impurity content, to meet customer demand for high purity;

Good electrical conductivity: physical method of preparing graphene powder with few defects, excellent electrical and thermal conductivity;

No dust pollution in liquid form, easy to add, and it is convenient for operation;

Good stability of the dispersed liquid, less agglomeration, the product maintains a monolayer dispersion state;

Graphene nanoplatelets dispersion liquid

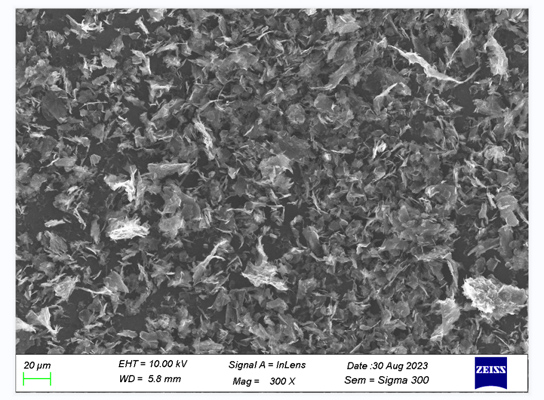

Scanning electron microscopy of Graphene Nanoplatelets Dispersion Liquid

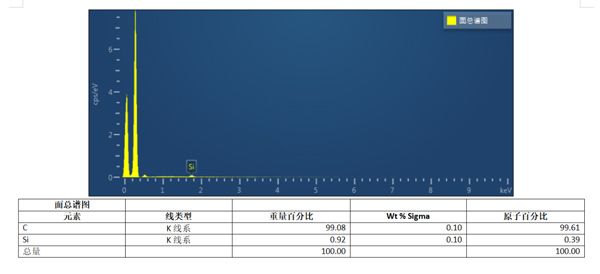

Elemental analysis diagram of Graphene Nanoplatelets Dispersion Liquid

Textile field: Graphene materials and ordinary textiles’s effective combination, can make the textile retain their own performance ,meanwhile access to graphene’s one or several special properties, such as conductive, flame-retardant, antibacterial, anti-ultraviolet ray, anti-electromagnetic radiation, magnetic therapy, anionic health care, etc., can be applied in the field of special protection, smart fabrics and so on;

Construction materials: Graphene construction materials are formed by using graphene as the core and compositing with other materials through its high strength and strain hardening properties. The characteristics of graphene flakes can be utilized to strengthen the thermal conductivity and strength of the material, while effectively reducing the density of the material. Usually in the concrete material to increase a strength level, a single square of concrete need to increase 30kg cement, if mixed with graphene, then to achieve the same strength level, can save cement about 10%. The advantages are high strength, good thermal conductivity, good emissivity and oxidation resistance.In 2018, a hospital in London, UK, applied a roof built with graphene material. This roof utilizes special 3D printing and steel structure, and through the high thermal conductivity of graphene material, the temperature inside the hospital will be drastically reduced in the summer, saving the hospital's air conditioning energy consumption.

Graphene anti-corrosion coatings: Graphene material in the sheet diameter is very small can still maintain a great diameter-thickness ratio, add a small amount of graphene in the coating on the line to effectively form a lap, the formation of a more complete shielding layer, delay the penetration of corrosive media, greatly reducing the permeability of chloride ions.On the other hand, the use of graphene's high conductivity, add a very small amount of zinc powder coating (<0.3%), the coating and zinc powder can form a conductive network, improve the utilization of zinc powder, so that the entire coating relative to the steel to become the "anode", and significantly improve the cathodic protection performance of the zinc powder primer.

Graphene lubricant: Traditional lubricant additives usually contain sulfur, phosphorus, chlorine and other elements, to bring greater harm to the environment, in order to create a green and efficient lubricant products, graphene has become the ideal choice, graphene lubrication and anti-wear performance is very excellent, when the number of layers of 2 ~ 3 layers, its friction is not zero but almost zero. Graphene lubricant can change the friction between the metal rotating parts into sliding between the layers of graphene sheets, and at the same time, it can also fill and repair the uneven pits on the metal surface to meet the dual needs of anti-wear and drag reduction, and prolong the service life of the engine. At the same time, based on graphene's antioxidant and anti-volatility, graphene lubricant can also save fuel and reduce carbon emissions, which is conducive to environmental protection. Currently several categories of graphene materials can achieve the effect of lubrication, but considering the problem of dispersion, the dispersion of graphene oxide is more advantageous.

The field of health: Graphene inherent properties determine that it can produce a wavelength of 5 ~ 15μm range of far-infrared radiation energy, and 4 ~ 15μm of far-infrared light is essential for the survival of plants and animals, "the light of life", biological tissues, cells and molecules of the chemical bond vibration, resonance wavelengths are located in most of the 4 ~ 15μm wavelength band. Most of the resonance wavelengths are located in the 4~15μm band when the chemical bonding of biological tissues and cells vibrate, which is basically coincident with the far infrared rays radiated by graphene, thus producing "resonance absorption". Far infrared rays have a strong penetrating ability, not only to the surface of the object, but also can be transported to the object inside the heat, absorbed by the human body can penetrate the skin 3 ~ 5nm, is the temperature of the deep skin rises, to promote blood circulation, and play a role in health care.

Masterbatch manufacturing industry: Graphene and its graphene oxide doping can change the physical and mechanical properties of polymers, graphene masterbatch as an additive can effectively change the tension, deformation and impact resistance of plastics, and enhance the resistance to ultraviolet rays. The incorporation and concentration of graphene and its derivatives can change the physical and mechanical properties of the polymer to be processed. Addition of the masterbatch to different polymers more or less improves the final properties of the material, for example:

Polypropylene (PP) with polypropylene-graphene masterbatch (MB-PP/GO) incorporation improves tensile strength (8%) and fracture rate (29%).

Additive for polyethylene (PE) with polyethylene-graphene masterbatch (MB-PE/GO) improves tensile strength (17%), flexural strength and breaking strength (66%).

Additives to polyethylene terephthalate (PET) with polyethylene terephthalate-graphene masterbatch (MB-PET/GO) improve moisture resistance, increase tensile strength (72.2%) and improve impact resistance.

Additive for polycarbonate (PC) with polycarbonate-graphene masterbatch (MB-PC/GO) improves moisture resistance and increases rupture resistance (276%).