MstnLand graphene based oil absorbing sponge is made by combining lipophilic and hydrophobic graphene with ordinary commercial porous sponges. It not only has the high strength and high resilience of sponges, but also has the hydrophobicity of graphene. It can be used to deal with the oil leakage accidents in the process of oil exploitation, refining and transportation, as well as the organic solvent pollution used and discharged in the chemical industry. The graphene modified sponge has a high adsorption capacity for various water pollutants such as dyes, oils and other organic solvents, and it's capable of absorbing various oil and organic solvent pollutants equivalent to 120 times its own weight.

MstnLand's graphene modified sponges can be used to deal with oil spills during oil extraction, refining and transportation, as well as organic solvent pollution used and emitted in the chemical industry. Using graphene modified sponge instead of oil absorbing felt to deal with oil spill pollution at sea, it can still float on the water after absorbing oil, easy to salvage and recycle, and can be reused more than thousands of times. When the graphene modified sponge reaches the absorption saturation state, it can be used repeatedly after physical extrusion treatment, and can keep the structure and performance without significant change and degradation.

Due to different application scenarios and technical specifications, MstnLand's graphene modified sponges can be customized according to customer requirements in various shapes, sizes and specifications, such as graphene sponge balls, graphene sponge blocks, graphene sponge boards, graphene sponge cakes, graphene sponge filters, etc.

Spherical graphene based oil absorbing sponge with 6cm diameter

Spherical graphene based oil absorbing sponge with 4cm diameter

Spherical graphene based oil absorbing sponge with 2cm diameter

Blocky graphene based oil absorbing sponge

Function: Can be used for oil slick, organic solvent recovery, which can be recycled by extrusion or negative pressure, after regeneration it can be reused.

| Item | Parameter |

| Color | Brown/black |

| Voidage | 5ppi~60ppi |

| Density | 15~50kg/m³ |

| Size | Non-standard and customizable |

| Shape | Non-standard and customizable |

| Origin | Beijing, Xiamen |

| Brand | SmartCmeta |

| Model | SY-GS |

| Price | Negotiable |

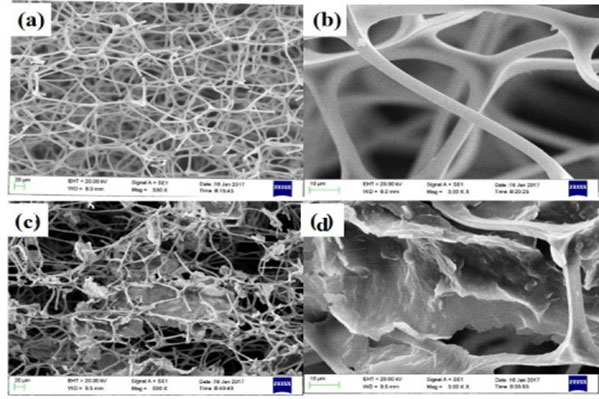

The above is the electron microscope scanning of the corresponding microstructure of blank sponge and graphene-supported sponge magnified 500 times (left) and 3000 times (right) respectively. Figure a and b show that the skeleton of blank melamine sponge is smooth and interwoven, forming multistage micropore structure with pore size ranging from tens to hundreds of microns. Therefore, oil or organic solvents can freely pass through the internal pores; The cross-linked skeleton structure of the sponge can also effectively support the weight of the adsorbed oil, giving the sponge a larger oil absorption capacity. According to the surface wetting theory, the material surface wettability is related to surface roughness and chemical properties. Because the blank sponge skeleton surface is smooth and flat, and contains a large number of hydrophilic groups, the oil-water separation selectivity is poor. As can be seen in Figure c and d, a large number of clumped and irregularly distributed graphene coatings appeared on the surface of the skeleton structure of the graphene loaded sponge. After local amplification, it could be clearly seen that there were crumpled protrusions with micro or nano size attached to the pore wall, which greatly increased the roughness of the sponge.

Super hydrophobic, contact angle can be more than 150°;

The adsorption rate is high, the adsorption capacity of crude oil can reach 120 times of its own weight;

High desorption rate, up to 95%;

After repeated use, the adsorption rate remains high after up to thousands of adsorption-desorption.

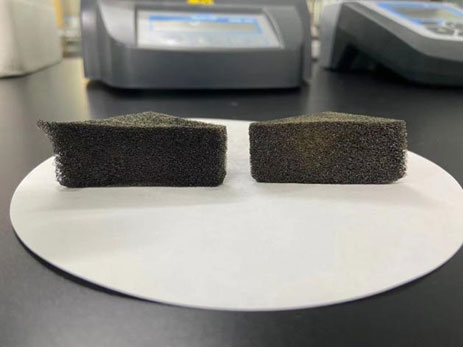

New graphene-based oil sponge (lift) VS graphene-based oil sponge that has been reused more than 1,000 times (right)

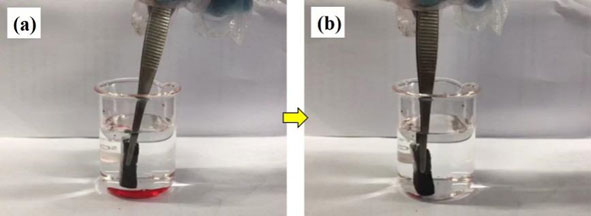

Water contact angle test diagram of graphene modified sponge

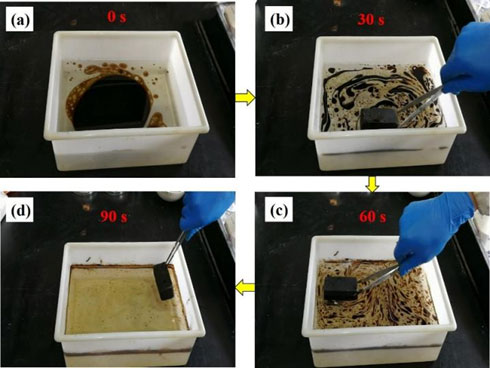

As shown in the figure above, add a simulated sea water containing 3.5% NaCl and pour 10 mL crude oil into the tank. A graphene modified sponge is held with tweezers and the oil on the water surface is absorbed back and forth. Under the action of the sponges' lipophilic and capillary forces, the crude oil from the water surface quickly penetrates into the sponges' pores. With the recovery process, the oil storage space of sponge gradually decreases, and the oil absorption rate decreases compared with the beginning. After 90s, most of the oil is recovered, and the sponge can continue to float on the water surface, which is conducive to salvage and recovery.

The water bottom of the beaker is trichloromethane stained with Sudan Red III. Dip the graphene modified sponge into the water bottom, and the trichloromethane is immediately adsorbed without absorbing water. It can be seen that in addition to oil recovery on the water surface, graphene modified oil absorbing sponge also has good selective adsorption for underwater oil or organic solvent leakage, and can be applied in the field of underwater oil and water separation. Sponges are good at oil philicity and hydrophobicity, and have strong selective absorption for heterogeneous oil-water mixing systems. They have great advantages in waters where large mechanical recovery equipment is difficult to operate, such as shoals and riverbanks.