Under the dual pressures of tightened environmental regulations and rising production costs, traditional adsorption materials have gradually become a bottleneck hindering factories' efforts to improve efficiency and quality. Issues such as rapid adsorption saturation, high operational costs, and the risk of secondary pollution urgently call for a technological innovation starting from the material source.

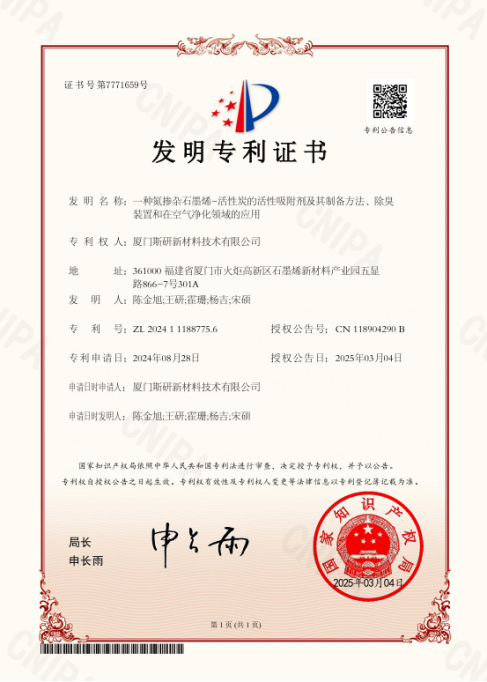

The graphene-activated carbon developed through independent R&D by SmartCmeta, a subsidiary of MSTN Group, has undergone systematic restructuring for various industrial adsorption scenarios, offering the market a novel solution.

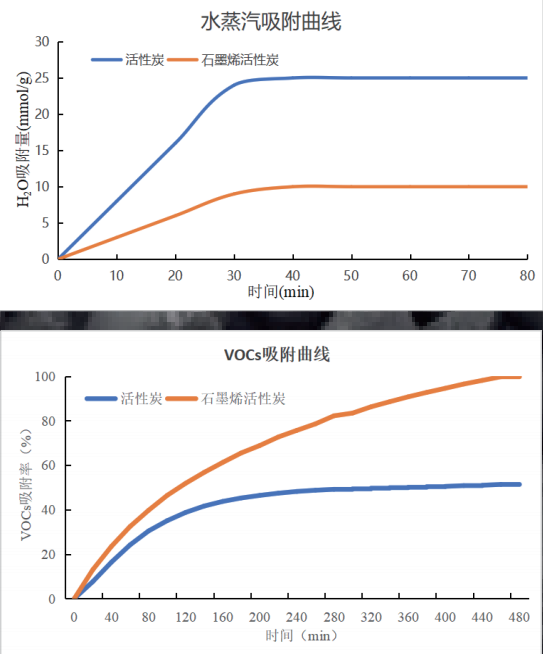

1. Adsorption performance doubles, effectively reducing overall costs

Ultra-high specific surface area: The three-dimensional network structure formed by graphene significantly enhances the specific surface area of activated carbon, providing a vast number of adsorption sites for pollutant removal.

The dynamic adsorption capacity is significantly enhanced, with the saturated adsorption of pollutants such as VOCs (volatile organic compounds), malodorous gases, sulfides, and heavy metal ions increasing by 2-5 times.

Significant economic benefits: By reducing the frequency of filter material replacement or regeneration, the adsorption cycle is extended; by improving the adsorption efficiency of the filter material, the equipment size is minimized, and the initial investment is reduced.

2. Fast mass transfer rate and high processing efficiency

Graphene's excellent high conductivity accelerates the efficiency of electron and material transfer, resulting in lower resistance, shorter residence time, and more thorough purification of waste gas or wastewater passing through the adsorption bed. Especially suitable for harsh working conditions with high air volume and low concentration, it can significantly improve equipment processing capacity.

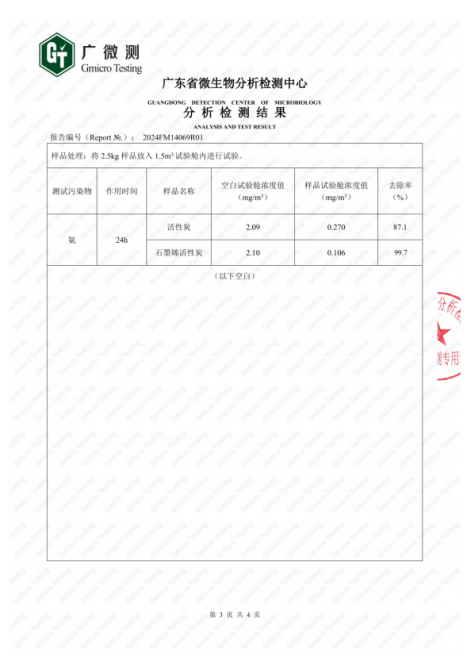

3. Strong antibacterial properties and stable system operation

Inhibition of biofilm growth: In wastewater treatment or high humidity exhaust gas treatment, traditional activated carbon is prone to microbial growth, leading to equipment blockage and odor generation.

Stable operation: Graphene has natural antibacterial properties, effectively preventing biological pollution and ensuring long-term stable operation of the system. Not easy to pulverize, reducing material loss and subsequent processing burden.

4. Strong designability, achieving precise governance

By modifying graphene activated carbon, its selective adsorption ability for specific pollutants can be enhanced, resulting in more precise purification and valuable resource recovery.

Based on the above characteristics, SmartCmeta can provide customized solutions for various industries:

1. VOCs exhaust gas treatment: suitable for end-point precision treatment in industries such as petrochemicals, spraying, printing, and pharmaceuticals. High adsorption efficiency, low desorption energy consumption, and higher purity of recovered solvent.

Before treatment

After treatment

2. Odor gas treatment: used in sewage treatment plants, garbage transfer stations, food processing plants, etc. It can efficiently remove small molecule odorous substances such as hydrogen sulfide, ammonia, thiols, etc., and does not produce any odor on its own.

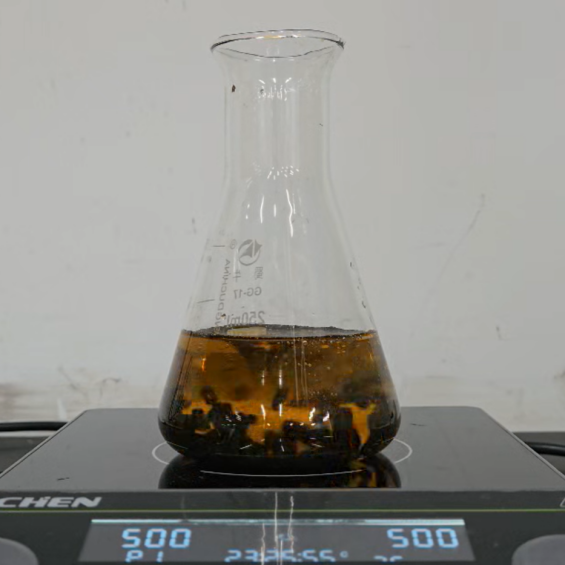

3. High standard wastewater treatment: Deeply removes recalcitrant COD, chromaticity, heavy metals (such as mercury and chromium), and trace organic compounds (EDC, PPCPs) from water, helping to achieve zero emissions or high standard reuse.

4. Chemical separation and purification: used as a catalyst carrier or adsorption medium for gas separation, solvent recovery, product refining, and other processes to improve product quality and absorption rate.

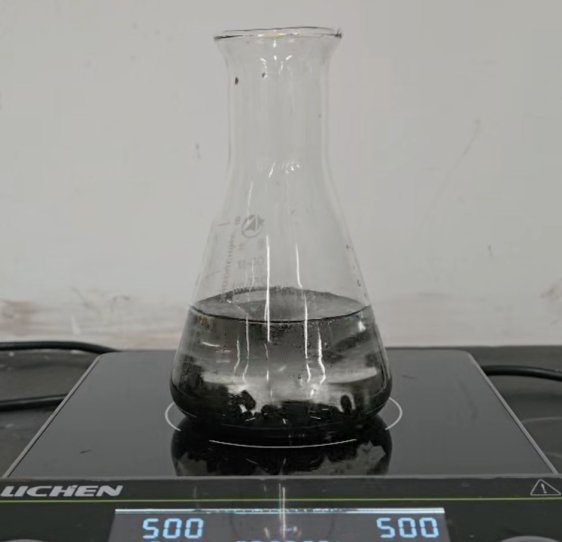

Before treatment

After treatment

Start Your Partnership With MstnLand

Learn More