Brass Gate Valves

Cast Iron Gate Valves

Cast Steel Gate Valves

Forged Steel Gate Valves

Stainless Steel Gate Valves

Rising Stem Gate Valves

Non-rising Stem Gate Valves

Double Disk Parallel Gas Gate Valves

Knife Gate Valves

Bellows Sealed Gate Valves

Cast Iron Globe Valves

Cast Steel Globe Valves

Forged Steel Globe Valves

Stainless Steel Globe Valves

Brass Globe Valves

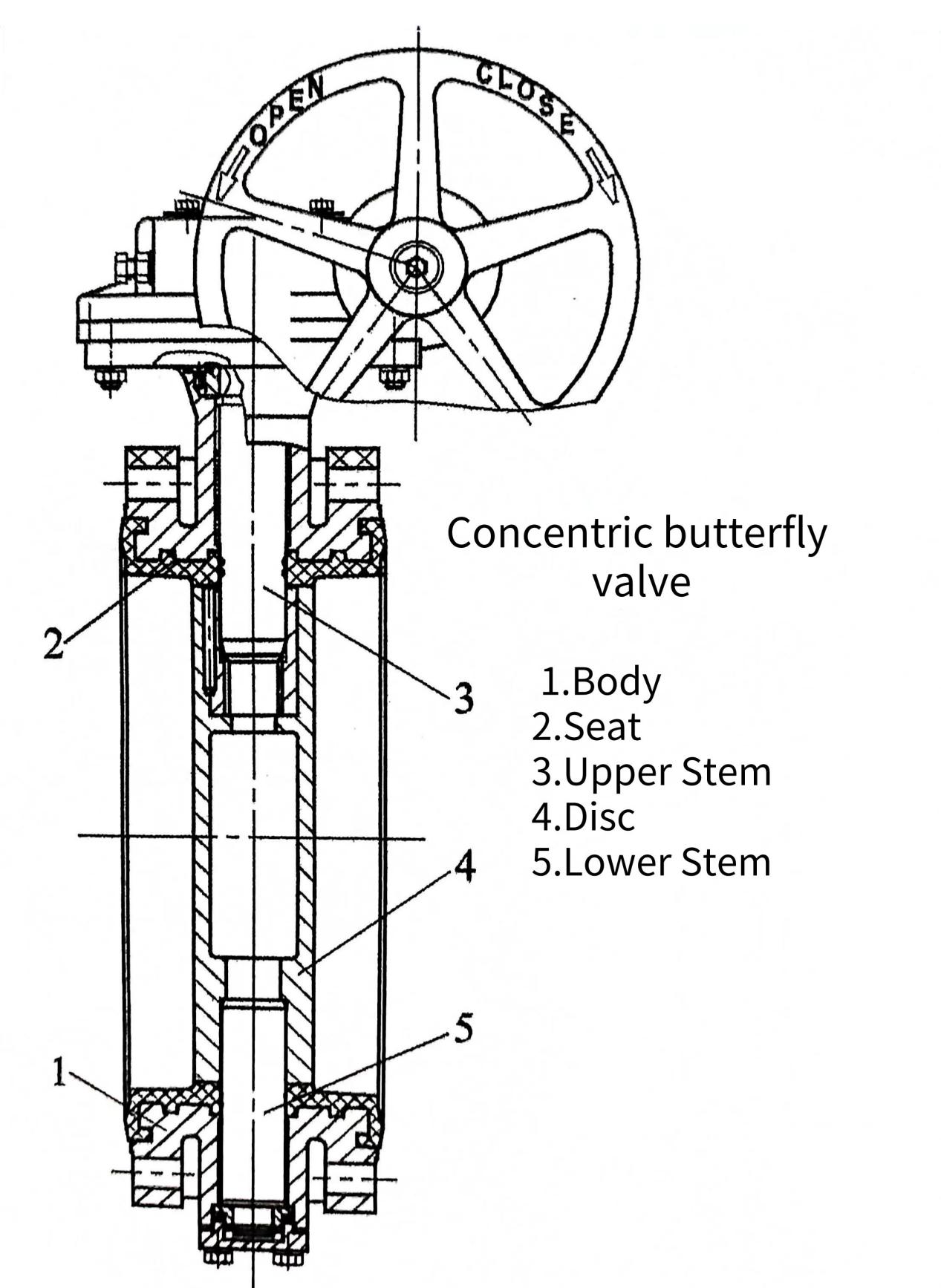

Wafer Type Butterfly Valves

Flange Type Butterfly Valves

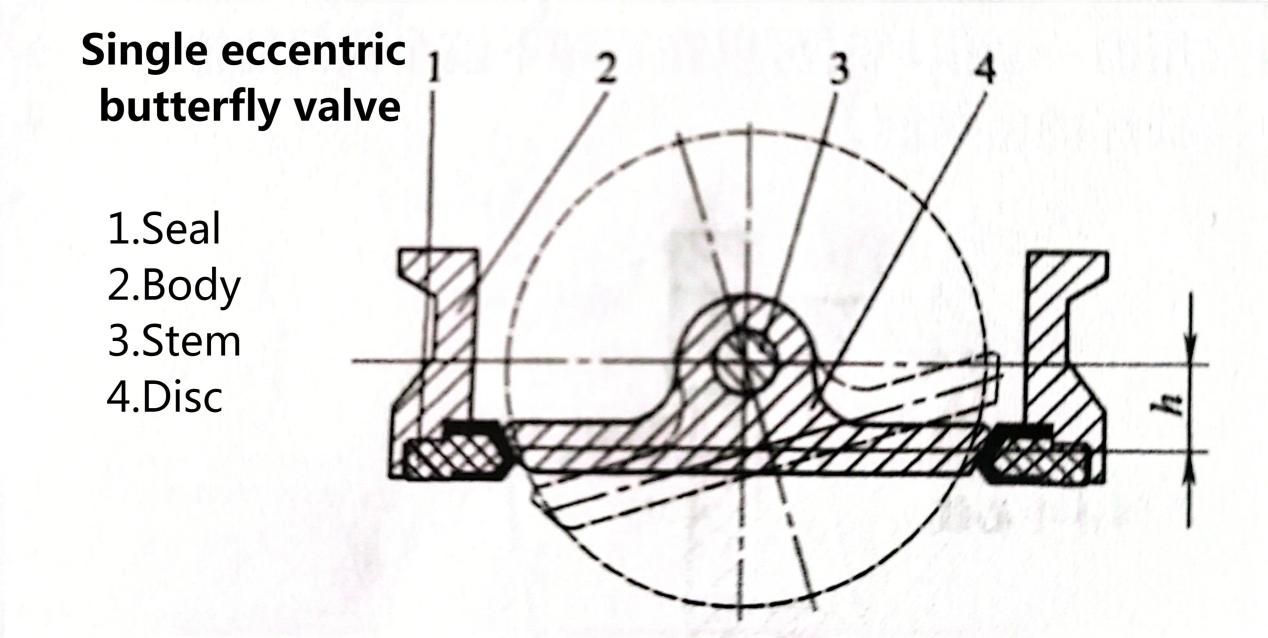

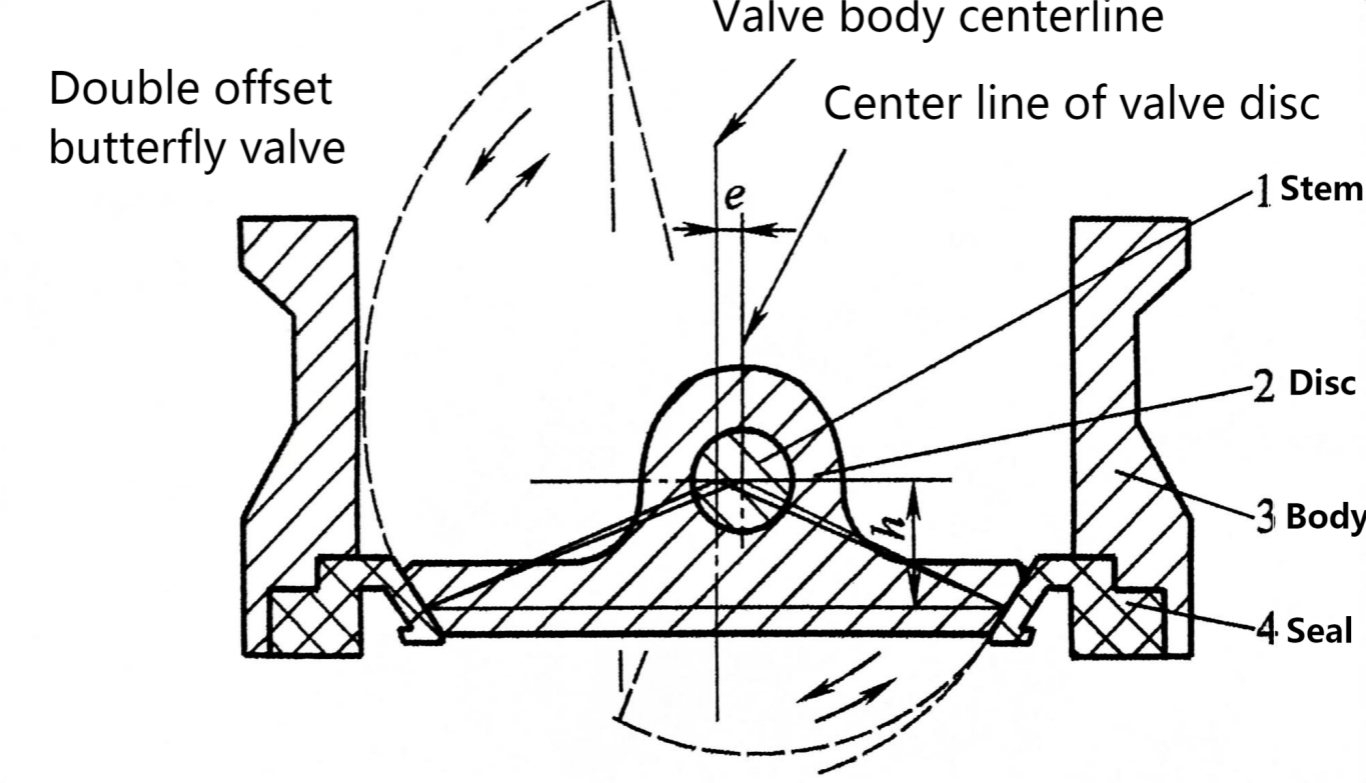

Eccentric Butterfly Valves

Lug Type Butterfly Valves

Cast Steel Check Valves

Cast Iron Check Valves

Stainless Steel Check Valves

Brass Check Valves

Lift Check Valves

Swing Check Valves

Forged Steel Check Valves

Cast Iron Ball Valves

Cast Steel Ball Valves

Stainless Steel Ball Valves

Brass Ball Valves

Fully Welded Ball Valves

Electric Ball Valves

Ceramic Core Ball Valves

Multiport Ball Valves

Rotary Valves

Top Entry Ball Valves

Floating Ball Valves

High Pressure Ball Valves

High Temperature Ball Valves

V-port Ball Valves

Cast Iron Butterfly Balance Valve

Cast Iron Internal Thread Globe Balance Valve

Brass Balance Valve

Number-lock Balance Valve

Closed Spring Loaded Full Bore Type Safety Valve

Closed Spring Loaded Low Lift Type Safety Valve

High Temperature And High Pressure Safety Valve

Pilot Operated Safety Valve

Spring Full Bore Type Safety Valve With Radiator

Spring Full Bore Type With Lever Safety Valve

Spring Loaded Low Lift External Thread Type Safety Valve

Spring Loaded Low Lift Type Safety Valve

Spring Loaded Low Lift Type With Lever Safety Valve

Stainless Steel Spring Loaded Full Bore Type Safety Valve With Handle

Twin Spring Type Safety Valve

LNG Filling Nozzle

Cryogenic Gas Return Nozzle

Cryogenic Gas Refueling Receptacle

Cryogenic Gas Relief Valve

Cryogenic Gas Shut-off Valve

Cryogenic Gas Breakaway Coupling

Cryogenic Gas Pressure Regulator

Cryogenic Gas Check Valve

Flanges

日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย

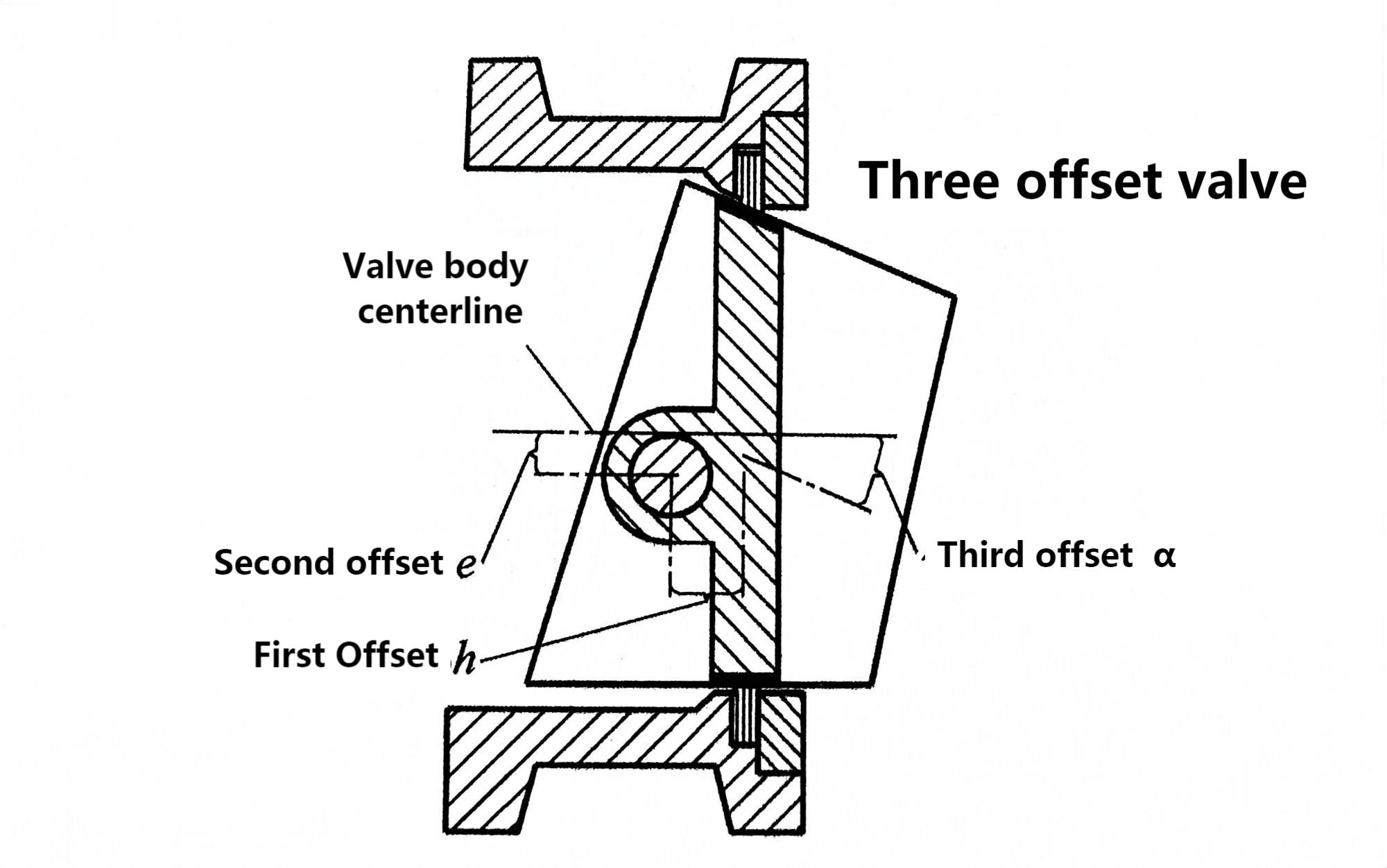

Triple eccentric butterfly valve, triple offset butterfly valve rotates the positive cone angle by an angle and changes it to an oblique cone angle, so that the eccentricity e can be reduced, and the torque to rotate and open the valve will also be reduced accordingly. Of course, this is just an intuitive understanding. In reality, where should the axis be set or should three-dimensional motion analysis be used to judge whether the sealing pair will interfere. It is worth pointing out that the sealing ring of the triple eccentric butterfly valve can not only be designed as a multi-layer type, but also other types of sealing types, and sometimes polymer non-metallic soft sealing materials can also be used. The final solution can be determined according to the process requirements. The purpose of designing the sealing of the triple offset butterfly valve is to better reduce the excessive opening torque of the valve, so that the operator can open and close the valve more conveniently, and at the same time, from a certain point of view, it can also prolong the service life of the valve stem.

Triple eccentric butterfly valve, triple offset butterfly valve rotates the positive cone angle by an angle and changes it to an oblique cone angle, so that the eccentricity e can be reduced, and the torque to rotate and open the valve will also be reduced accordingly. Of course, this is just an intuitive understanding. In reality, where should the axis be set or should three-dimensional motion analysis be used to judge whether the sealing pair will interfere. It is worth pointing out that the sealing ring of the triple eccentric butterfly valve can not only be designed as a multi-layer type, but also other types of sealing types, and sometimes polymer non-metallic soft sealing materials can also be used. The final solution can be determined according to the process requirements. The purpose of designing the sealing of the triple offset butterfly valve is to better reduce the excessive opening torque of the valve, so that the operator can open and close the valve more conveniently, and at the same time, from a certain point of view, it can also prolong the service life of the valve stem.